Daily Report

The University of Texas at Austin and Geotek are in Cameron, Texas, conducting land-based coring tests of the Pressure Core Tool with Ball Valve (PCTB), a highly complex piece of engineering designed to core, contain and recover samples of methane hydrate bearing sediments. The primary goal of the project is to test the tool, gain insights into its operation, and train personnel who will join the mission team when UT returns to the Gulf of Mexico in 2022. This is third of five daily reports.

EXECUTIVE SUMMARY

Two cutting shoe pressure cores were taken. There was ~80% core recovery in both cases. However, in both cases, the ball valve jammed and did not seal. The working interpretation is that high flow rates (400 & 600 gpm) may have driven detritus between the seal carrier and housing, creating enough friction to prevent the ball valve from closing completely. In the next tests, we will reduce the flow rates and determine whether this improves the sealing.

OPERATIONAL RESULTS

0700: Daily briefing, safety for all newly arrived personnel and planned operations for the day.

0730: Make up PCTB-CS BHA. Waiting on assembled PCTB-CS for spacing out in BHA.

0930: Begin spacing out PCTB-CS.

1130: Spacing out complete, RIH w/bit.

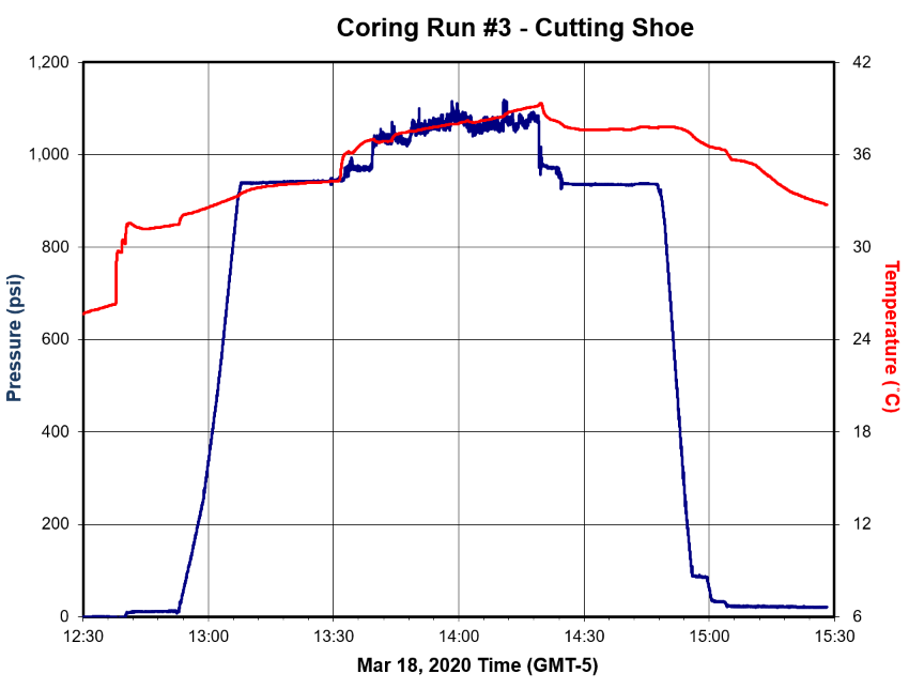

1330: Begin cutting core 03CS at 1831.5 ft.

- 5500 – 7500 klb WOB

- 600 gpm

- 70 rpm

- 1600 psi

1430: Stop coring core 03CS at 1841 ft, circulate hole, rig up wireline to recover 03CS.

1515: Core 03CS in service conex. Ball jammed partially open.

- No pressure.

- ~7.5 ft of core.

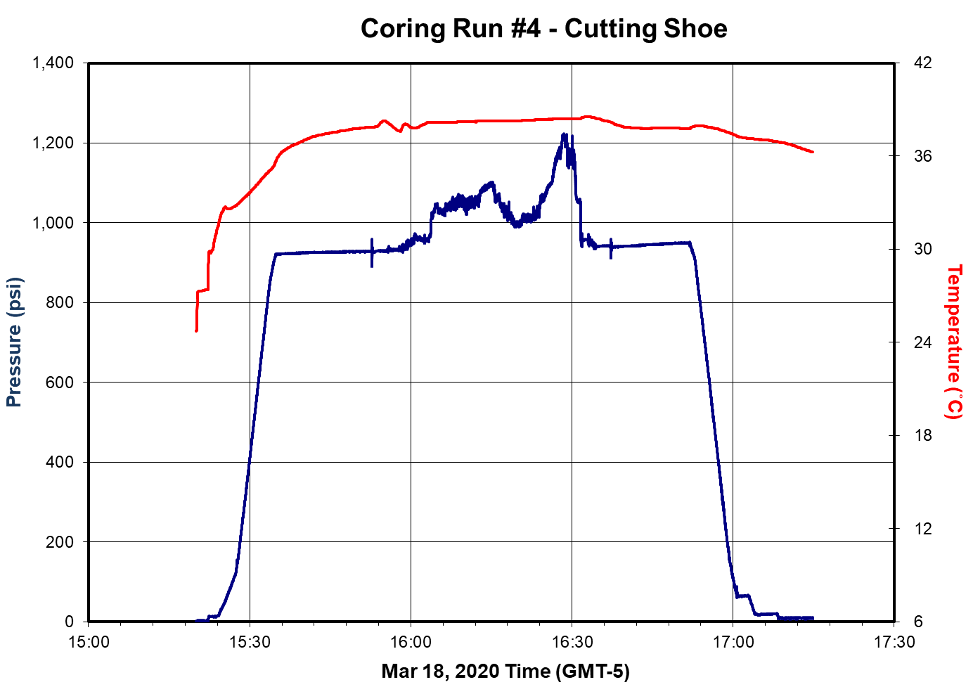

1545: RIH w/04CS to cut 1/2 core.

1615: Begin cutting core 04CS.

- 4500 klb WOB

- 400 gpm

- 70 rpm

- 800 psi

1645: Stop cutting core 04CS at 1843.5 ft.

1730: Core 04CS at service conex. Ball valve jammed partially open.

- No pressure.

- ~2 ft of core.

1800: Review test results to date.

Discussion

The ball valve jamming appears to be a result of detritus laden drilling mud migrating upward between the seal carrier and housing, creating enough friction to prevent the ball valve from closing completely. The problem may have been exasperated by the high flow rates used during the testing. The decision was made to employ lower flow rates in additional tests to see if that alleviates the problem.

Night Shift Operations Plan

- Pull back to shoe.

- Trip back to TD and circulate for 1 hour just prior to morning shift change.

CORE RESULTS

Coring Test 3 (core CTTF-03CS): Coring advanced the bit from 1831.5 to 1841.0 ft. 9.5 ft of formation were penetrated over 50 minutes. The ball valve did not close, and pressure was not maintained in the autoclave.

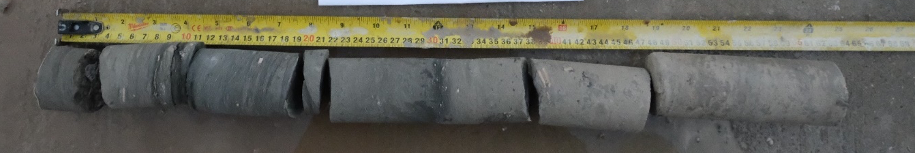

114” (290 cm) of core was recovered in CTTF-03CS. Core recovery was 79%. The core was largely cylindrical with no marked variations in diameter. The core was predominantly composed of light gray indurated carbonate rich rock. Occasional layers of dark gray to charcoal fissile shale was found One ~15 cm section of almost pure shale was encountered. The core was cut into three sections: CTTF-03CS-1, CTTF-03CS-2, and CTTF-03CS-3. The sections were photographed, labelled, put back in the core liner and preserved. The core quality was perhaps more broken up than the previous face-bit cores.

Coring Test 4 (core CTTF-04CS): Coring advanced the bit from 1841.0-1843.5’ MD from 16:00 to 16:34 with 600 gal/min circulation. This core was cut shorter to test the concept that the core length was affecting the ability of ball valve to seal.

0.62 m of core (2.0 ft) of core were recovered resulting in a core recovery of 80%. The core was very good quality and was largely cylindrical with no marked variations in diameter. The core was predominantly composed of light gray indurated carbonate-rich rock. At the top of the core, few layers of dark gray to charcoal shale were found which transitioned to pure limestone. The core was left in one section: 1) CTTF-04CS-1 (0-0.62 m).