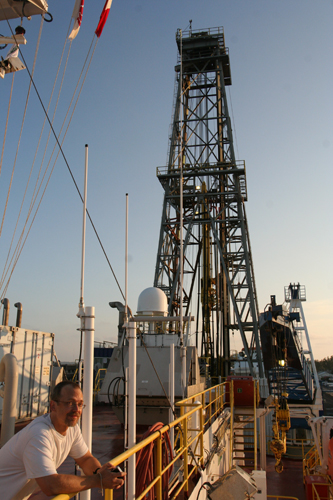

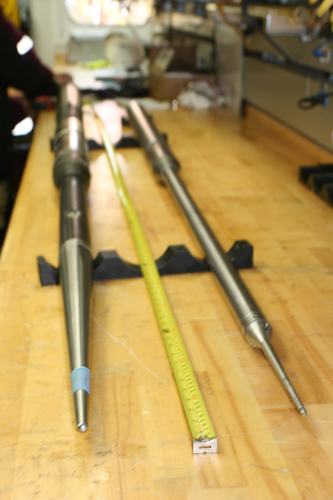

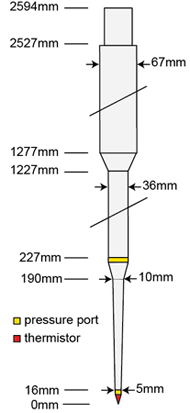

The Temperature-2-Pressure Probe is a pore pressure penetrometer jointly developed by University of Texas at Austin and MIT to measure in-situ pore pressure and temperature in undisturbed sediments at the base of a borehole. Tool development began in 2003; it was deployed in and around Boston, MA in 2004 and deployed on the IODP’s JOIDES Resolution drillship in June 2005 on IODP Expedition 308. The T2P is approximately eight feet long and decreases in diameter from ~2.75″ at the top to a narrow tip, which houses a thermistor and pressure sensor; a second pressure sensor is located at the larger diameter shaft behind the tip (thus 1 temperature and 2 pressure or “T2P”). The probe is driven into a formation and left in-place measuring the dissipation of temperature and pressure on an onboard computer. Following Expedition 308, we determined that an improvement to the Colleted Delivery System would be required to produce optimal results. The subsequent improvement to the delivery system was initially the ‘Motion De-Coupled Hydraulic Delivery System’ (MDHDS) but has evolved further to become the PDT – Probe Delivery Tool. As part of this improvement, the T2P required physical modification to its diametric size. To meet this reduction, the IODP Texas A&M developed the Common Data Acquisition (CDAQ) system for the T2P. After rigorous laboratory and field testing the T2P and engineering team completed a successful round of engineering tests on IODP Expedition 342 in June 2012. Currently the T2P is housed at the University of Texas and is available for deployment.

The T2P and PDT have greatly improved in-situ temperature and pressure measurements. Prior to the PDT, penetrometers were deployed using the Colleted Delivery System. With this system, failure due to premature removal occurred 80% of the time (due to ship heave), additionally, it was difficult to align the tool during penetration resulting in bent or broken tips. Now, with the PDT and re-designed T2P, a more slender tool delivered through a well-designed delivery system results in near perfect execution, with no bent or broken tips.