Daily Report

The University of Texas at Austin and Geotek are in Cameron, Texas, conducting land-based coring tests of the Pressure Core Tool with Ball Valve (PCTB), a highly complex piece of engineering designed to core, contain and recover samples of methane hydrate bearing sediments. The primary goal of the project is to test the tool, gain insights into its operation, and train personnel who will join the mission team when UT returns to the Gulf of Mexico in 2022. This is fourth of five daily reports.

EXECUTIVE SUMMARY

Two short cutting shoe pressure cores (e.g. 1 ft’) were taken with high recovery. However, the ball valve was partially closed and thus did not seal in either run. The final deployment of the PCTB was to exercise it in the casing without coring (a ‘water core’). The ball valve did not fully close. The Probe Deployment Tool (PDT) was then made up and run in the hole. When the tool was lowered on wireline, it unlatched at a depth of 348 ft. The PDT landed in the BHA and was then retrieved without incident. The PDT deployment was unsuccessful.

OPERATIONAL RESULTS

0700: Daily briefing, safety and planned operations for the day.

0730: RIH from shoe to TD and circulate in preparation for CS-3 [renamed CCTF-05CS].

- Note, rig shut down due to lightning in the area preventing night crew from tripping to TD and circulating.

0800: Circulating hole.

0900: Pick up core CS-3 [CCTF-05CS].

1020: Begin cutting core CS-3 [CCTF-05CS] at 1843.5 ft.

- 1.0 WOB

- 30 gpm

- 70 rpm

- 50 psi

1100: Stop coring at 1843.8 ft.

1140: Core CS-3 [CCTF-05CS] at service conex. No pressure. It appears the ball was held partially open by either detritus or a short core stub. ~1 ft of core recovered. DST record shows an attempt to boost the autoclave pressure.

1245: RIH with core CS-4 [CCTF-06CS] at 1843.8 ft.

1315: Start cutting core CS-4 [CCTF-06CS] at 1843.8 ft.

- 1.0 WOB

- 100 gpm

- 70 rpm

- 100 psi

1335: Stop cutting CS-4 [CCTF-06CS] at 1844.2 ft.

1415: Core CS-4 [CCTF-06CS] at service conex. Ball did not fully close. No pressure.

1600: RIH with CS-5 [CCTF-07CS] Water Core bit at 1235 ft inside casing.

1645: CS-5 [CCTF-07CS] water core at service conex. Ball did not fully close. No pressure.

1815: RIH with Probe Deployment Tool (PDT) to 348 ft when weight was lost.

- POOH with RPT only.

- RIH with GS pulling tool.

- Latch into PDT and recover. PDT stoked out when recovered.

2000: All tools laid out on cat walk. Shut down for the night.

Night Shift Operations Plan

1) POOH, lay out drill pipe.

CORE RESULTS

Coring Test 5 (core CTTF-05CS): Coring advanced the bit from 1843.5 to 1843.8 ft. 0.3 ft of formation were penetrated over 45 minutes. The ball valve did not close, and pressure was not maintained in the autoclave.

7” (18 cm) of core was recovered in CTTF-05CS. The core was largely cylindrical with no marked variations in diameter. The core was predominantly composed of light gray indurated carbonate rich rock. One 4 cm layer of dark gray to charcoal fissile shale was found. The core was photographed, labelled, put back in the core liner and preserved. The core quality is very good.

Coring Test 6 (core CTTF-06CS): Coring advanced the bit from 1843.8 to 1844.2 ft. 9.5 ft over 20 minutes. No core was recovered.

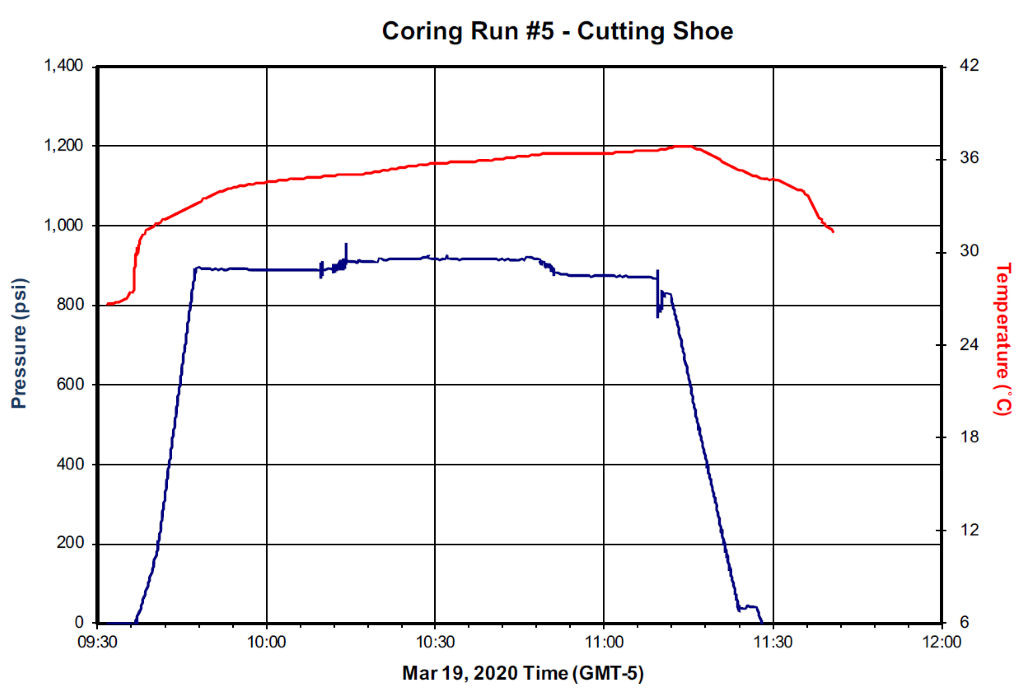

Coring Test 7: No core was taken in this coring test. A ‘Water Core’ was taken at 1235 ft inside casing.

PDT & T2P RESULTS

The Probe Deployment Tool (PDT) is a device designed to land into the BHA. Upon landing it unlatches the inner rod subassembly allowing the probe to be driven by either the weight of the rod, or pump pressure, into the formation. At that point, the probe is independent of the drill string, which compensates for any residual heave. We deployed the PDT with the BHA at 1235 ft inside casing. We began to build the tool at 17:00. We started to run the tool at 18:00. The tool was lost at 348 ft as recorded by a dramatic reduction in weight on the slickline. A large banging noise was heard which was interpreted to record the impact of the PDT when it rested in the BHA. The tool was quickly recovered with the GS pulling tool. When recovered, the tool was extended: the inner rod subassembly was run out from the outer barrel. Upon recovery, the very tip of the probe was snapped off (1cm), but there was no other apparent damage. No data were recorded by the probe tool.

PRESSURE AND TEMPERATURE (DST) RESULTS

DST pressure and temperature record for CTTF-07CS. (not yet available)