Daily Report

The University of Texas at Austin and Geotek are in Cameron, Texas, conducting land-based coring tests of the Pressure Core Tool with Ball Valve (PCTB), a highly complex piece of engineering designed to core, contain and recover samples of methane hydrate bearing sediments. The primary goal of the project is to test the tool, gain insights into its operation, and train personnel who will join the mission team when UT returns to the Gulf of Mexico in 2022. This is second of five daily reports.

OPERATIONAL RESULTS

0700: Daily briefing, safety for all newly arrived personnel and planned operations for the day.

0730: RIH w/pipe from casing shoe at ~1300 ft to TD and circulate.

0800: Rig up wireline.

1030: RIH with core barrel.

1100: Begin cutting core FB-1 ~1815.1 ft.

- 400 gpm

- 70 rpm

- 4200 WOB

- 775 pump pressure

1215: Stop coring @ 1821.7 ft.

- RIH to recover core FB-1.

1300: Core FB-1 in service conex.

- Pressure = ~2100 psi

- Core length = ~5.5 ft

- Cored interval = ~6.6 ft.

- Note that the core catcher (wedge/spring) stuck to the top of the core and rode up inside the liner with the core.

1415: Pick up core barrel for core FB-2.

1500: Cutting core FB-2

- 5500 WOB

- 72 RPM

- 600 gpm

- 1590 pump pressure

1545: Stop coring @ 1831.5 ft

- RIH w/WL to recover core FB-2

1645: Core FB-2 in service conex.

- Ball closed

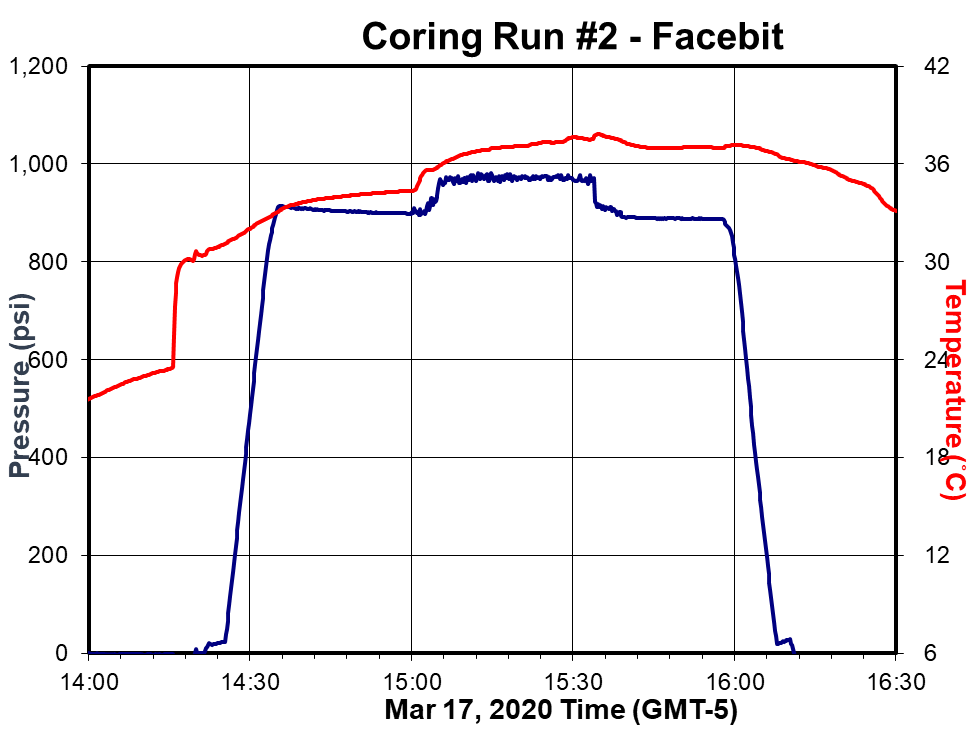

- No retained pressure in autoclave. The autoclave held pressure when pressurized in the service conex prior to opening. The DST recorded a change in hydrostatic pressure as the tool was recovered indicating that the leak was present over the entire trip from TD to the rig floor.

- Final reservoir pressure = 1615 psi

- Reservoir fill pressure = 8000 psi

Night Shift Operations Plan

- Pull out of hole to rig floor.

- Prepare for switching to cutting shoe BHA in morning.

Daily Summary

1) The day began at 0700 with a safety briefing for all newly arrived personnel.

2) The hole depth before coring was 1815MD/1811 TVD.

3) We Advanced the bit by coring (and now at 1821.69MD). Core came to drilling floor at 12:55.

4) Started core

CORE RESULTS

Coring Test 1 (core CTTF-1FB): 6.6 ft of formation were penetrated over 48 minutes. At 11:45, the rate of penetration slowed, it was interpreted that the bit was balling, and we ceased coring 11:52. The ball valve closed, and pressure recorded in the autoclave was 2100 psi.

70” (178 cm) of core was recovered in CTTF-1FB. Core recovery was 91%. The core was largely cylindrical with no marked variations in diameter. The core was predominantly composed of light gray indurated carbonate rich rock. Occasional layers of dark gray to charcoal fissile shale was found One ~15 cm section of almost pure shale was encountered. The core was cut into two sections: CTTF-1FB-1 and CTTF-1FB-2. The sections were photographed, labelled, put back in the core liner and preserved.

Coring Test 2 (core CTTF-2FB): Coring advanced the bit from 1821.7-1831.4’ MD from 15:00 to 15:34 with 600 gal/min circulation.

2.7 m of core (8.9 ft) of core were recovered resulting in a core recovery of 92%. The core was largely cylindrical with no marked variations in diameter. The core was predominantly composed of light gray indurated carbonate rich rock. Occasional layers of dark gray to charcoal fissile shale was found The core was cut into 3 sctions: 1) CTTF-2FB-1: 0-0.90, 2) CTTF-2FB-2: 0.90-1.90 m, and 3)CTTF-2FB-3: 1.90-2.70 m.